Услуги

JSC "PPO EVT" is a dynamically developing company. In the modern world of high technology, the quality of products is the main principle of competitiveness. Keeping pace with time, the factory was being rapidly reconstructed, upgrading equipment and introducing latest technologies.

JSC "PPO EVT" is a dynamically developing company. In the modern world of high technology, the quality of products is the main principle of competitiveness. Keeping pace with time, the factory was being rapidly reconstructed, upgrading equipment and introducing latest technologies. We offer you the following services:

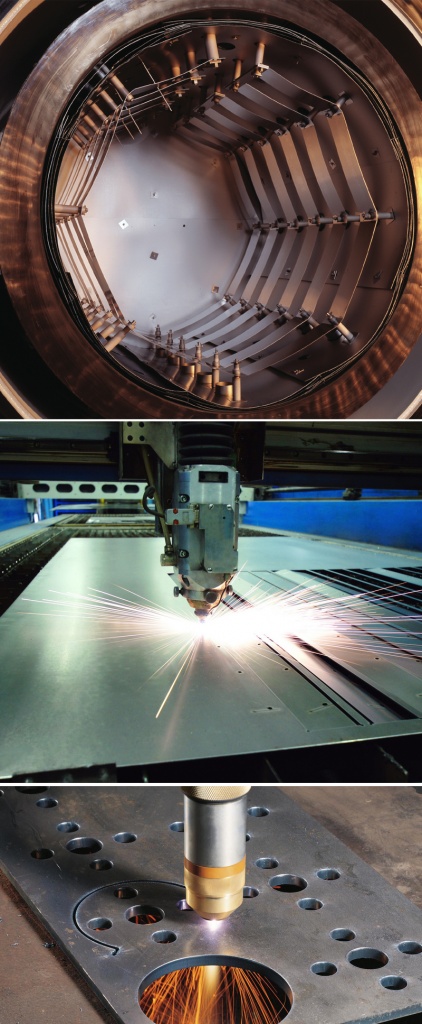

1. Tool Production Department renders the following services:

- vacuum treatment of steel;

- vacuum treatment of steel;- laser cutting of steel and nonferrous alloys;

- plasma cutting of steel.

2. Casting and Plastic Production Department offers the services on component production:

- components made of aluminum alloys by the die casting technique on Italian moulding machines;

- components made of aluminum alloys by the die casting technique on Italian moulding machines; - components made of thermoplastic materials on thermoplast automates;

- components made of thermoset materials and rubber stocks by the technique of injection and compression moulding on hydraulic press;

- components made of synthetic rubber (EPDM) by the die-casting technique on vertical injection machine;

- isolation tubes by the profiling technique on horizontal screw machine.

3.Galvanic coating of components made of steel, copper, copper alloys, aluminum and aluminum alloys of the following types:

- Zinc coating;

- Nickel coating;

- Copper coating;

- Coating with tin-bismuth alloy;

- Chroming;

- Passivation;

- Oxidation;

- Nickel coating.

4. Enamel coating of components of any complexity

The factory performs enamel coating of components of any complexity in any quality, using the equipment of the companies «Wagner Itep» and «Gema» with high quality enamels, provided by the company «Ferro».

The factory performs repair of enamel coating of household appliances (black, white colors).

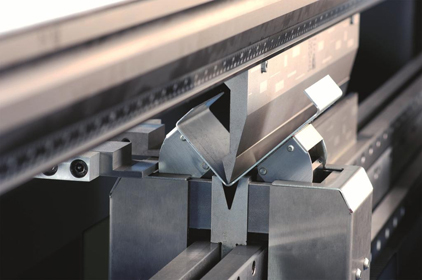

5. Treatment and cutting of sheet material

- cutting out and/or punching of metal;

- die forming;

- laser cutting of components and workpieces.

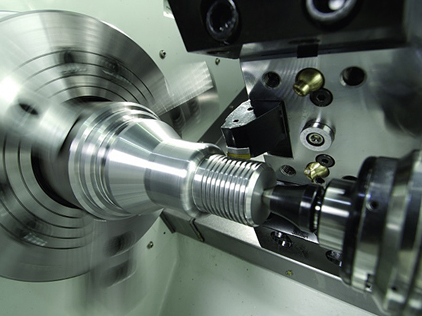

6. Milling and lathe processing on CNC machine

7. Constructional design and manufacturing of technological tool-sets

The Design Engineering Bureau of the company JSC “PPO EVT” offers its services on constructional design and manufacturing of technological tool-sets of any complexity according to drawings/sketches, 3D models and samples of components, provided by a customer.

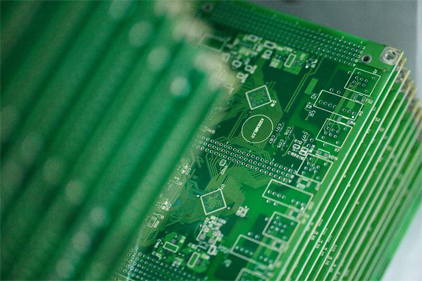

8. Printed circuit board (PCB) manufacturing

The factory manufactures double-sided printed circuit boards by the composite positive technique and multilayer printed board by the plating technique of through holes.

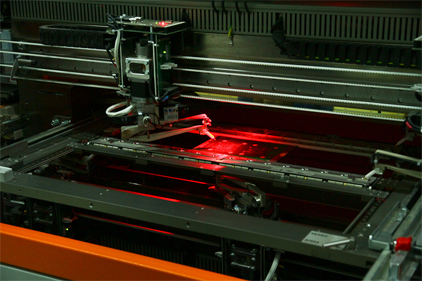

9. Automatic assembling of printed boards

Technological capabilities of the factory allows to perform automatic assembling of chips with minimal body dimensions 01005 (400x200 micrometer), microcircuits with lead pitch from 0,3 mm, and microcircuits in the units TQFP, TSOP, PLCC, JLEAD, QFP, SOIC (SOJ), BGA and other elements, meant for SMD assembling.

Third-party Orders Department (8412) 49-60-65, e-mail:pdo@ppoevt.ru

-

Leader Today JSC ‘’PPO EVT’’ is one of the largest manufacturers of household appliances

Leader Today JSC ‘’PPO EVT’’ is one of the largest manufacturers of household appliances -

Where to buy More than 1.200 sales offices, 230 dealers and partners of the company around Russia

Where to buy More than 1.200 sales offices, 230 dealers and partners of the company around Russia -

Service center Every day our specialists work to obtain excellent quality and receive good feedbacks from our customers

Service center Every day our specialists work to obtain excellent quality and receive good feedbacks from our customers -

Harmony Collection of built-in appliances which harmoniously transform usual living space into the standard of style and comfort

Harmony Collection of built-in appliances which harmoniously transform usual living space into the standard of style and comfort